Early Steam Engines

A steam engine, or a heat engine that performs mechanical work using steam, was first described in the 1st century CE. However, it was the designs of Savery’s engine in 1698 and Newcomen’s engine in 1712 that were first used commercially and inspired the further development of steam technology.

Learning Objectives

List the early iterations of the steam engine

Key Takeaways

Key Points

- A steam engine is a heat engine that performs mechanical work using steam. The history of the steam engine stretches back as far as the 1st century CE. Greek mathematician Hero of Alexandria described the first recorded rudimentary steam engine, known as the aeolipile. In the following centuries, the few early steam-powered engines were, like the aeolipile, experimental devices used by inventors to demonstrate the properties of steam.

- The first commercial steam-powered device was a water pump developed in 1698 by Thomas Savery, who demonstrated it to the Royal Society a year later. The patent has no illustrations or even description, but in 1702 Savery described the machine in his book The Miner’s Friend, or, An Engine to Raise Water by Fire, in which he claimed that it could pump water out of mines.

- Savery’s engine received some use in mines and pumping stations and for supplying water wheels used to power textile machinery. An attractive feature of the Savery engine was its low cost. Bento de Moura Portugal introduced an ingenious improvement of Savery’s construction “to render it capable of working itself,” as described by John Smeaton in 1751. It continued to be manufactured until the late 18th century.

- The first commercially successful engine that it could generate power and transmit it to a machine was the atmospheric engine, invented by Thomas Newcomen around 1712. It was an improvement over Savery’s steam pump, using a piston as proposed by Papin. Newcomen replaced the receiving vessel (where the steam was condensed) with a cylinder containing a piston based on Papin’s design. Instead of the vacuum drawing in water, it drew down the piston.

- The engine was relatively inefficient and in most cases was used for pumping water. It was employed for draining mine workings at depths previously impossible and for providing a reusable water supply for driving waterwheels at factories sited away from a suitable “head.” Water that passed over the wheel was pumped back up into a storage reservoir above the wheel.

- Newcomen’s engine held its place without material change for about 75 years, spreading gradually to more areas of the UK and mainland Europe. Experience led to better construction and minor refinements in layout. Its mechanical details were much improved by John Smeaton, who built many large engines of this type in the early 1770s; his improvements were rapidly adopted. By 1775, about 600 Newcomen engines had been built.

Key Terms

- beam engine: A type of steam engine in which a pivoted overhead beam is used to apply force from a vertical piston to a vertical connecting rod. This configuration, with the engine directly driving a pump, was first used by Thomas Newcomen around 1705 to remove water from mines in Cornwall.

- aeolipile: A simple bladeless radial steam turbine, also known as a Heron’s engine, that spins when the central water container is heated. Torque is produced by steam jets exiting the turbine, much like a tip jet or rocket engine. In the 1st century CE, Hero of Alexandria described the device, and many sources give him the credit for its invention.

- Steam engine: A heat engine that performs mechanical work using steam as its working fluid.

- atmospheric engine: An engine invented by Thomas Newcomen in 1712, often referred to simply as a Newcomen engine. The engine operated by condensing steam drawn into the cylinder, thereby creating a partial vacuum and allowing the atmospheric pressure to push the piston into the cylinder. It was the first practical device to harness steam to produce mechanical work.

Introduction of the Steam Engine

A steam engine is a heat engine that performs mechanical work using steam. The history of the steam engine stretches back as far as the 1st century CE. Greek mathematician Hero of Alexandria described the first recorded rudimentary steam engine, known as the aeolipile. In the following centuries, the few early steam-powered engines were, like the aeolipile, experimental devices used by inventors to demonstrate the properties of steam. A rudimentary steam turbine device was described by Taqi al-Din in 1551 and by Giovanni Branca in 1629. Jerónimo de Ayanz y Beaumont received patents in 1606 for 50 steam-powered inventions, including a water pump for draining inundated mines. Denis Papin, a Huguenot refugee, advanced the construction of the steam digester in 1679 and first used a piston to raise weights in 1690.

Savery’s Engine

The first commercial steam-powered device was a water pump developed in 1698 by Thomas Savery, who demonstrated it to the Royal Society a year later. The patent has no illustrations or even description, but in 1702 Savery described the machine in his book The Miner’s Friend, or, An Engine to Raise Water by Fire, in which he claimed that it could pump water out of mines. Savery’s engine had no piston and no moving parts except the taps. It was operated by first raising steam in the boiler and then admitting it to one of the first working vessels, allowing it to blow out through a downpipe into the water to be raised. When the system was hot and therefore full of steam, the tap between the boiler and the working vessel was shut and, if necessary, the outside of the vessel was cooled. This made the steam inside it condense, creating a partial vacuum, and atmospheric pressure pushed water up the downpipe until the vessel was full. At this point, the tap below the vessel was closed and the tap between it and the up-pipe opened, and more steam was admitted from the boiler. As the steam pressure built up, it forced the water from the vessel up the up-pipe to the top of the mine.

The 1698 Savery Engine, Institute of Human Thermodynamics and IoHT Publishing Ltd.

Savery’s original patent of July 1698 gave 14 years’ protection. The next year, an Act of Parliament was passed, which extended his protection for a further 21 years. This Act became known as the Fire Engine Act. Savery’s patent covered all engines that raised water by fire and thus played an important role in shaping the early development of steam machinery in the British Isles.

Following Savery’s design, small engines were effective but larger models were problematic. They proved only to have a limited lift height and were prone to boiler explosions. The engine received some use in mines, pumping stations and for supplying water wheels used to power textile machinery. An attractive feature of the Savery engine was its low cost. Bento de Moura Portugal introduced an ingenious improvement of Savery’s construction “to render it capable of working itself,” as described by John Smeaton in 1751. It continued to be manufactured until the late 18th century. One engine was still operating in 1820.

Newcomen’s Engine

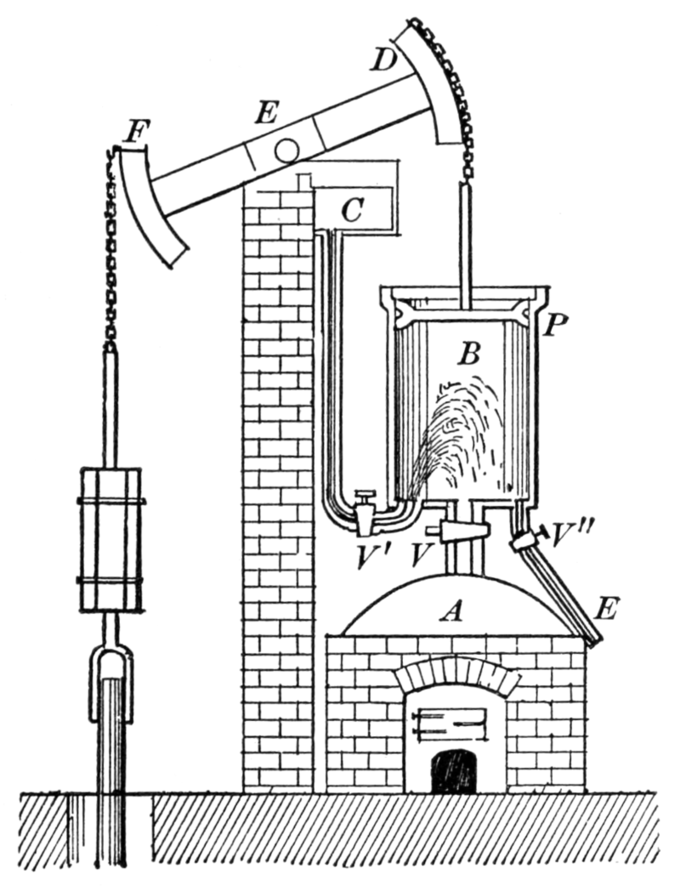

The first commercially successful engine that it could generate power and transmit it to a machine was the atmospheric engine invented by Thomas Newcomen around 1712. It was an improvement over Savery’s steam pump, using a piston as proposed by Papin. Newcomen replaced the receiving vessel (where the steam was condensed) with a cylinder containing a piston based on Papin’s design. Instead of the vacuum drawing in water, it drew down the piston. This was used to work a beam engine, in which a large wooden beam rocked upon a central fulcrum. On the other side of the beam was a chain attached to a pump at the base of the mine. As the steam cylinder was refilled with steam, readying it for the next power stroke, water was drawn into the pump cylinder and expelled into a pipe to the surface by the weight of the machinery.

Newcomen and his partner John Calley built the first successful engine of this type at the Conygree Coalworks near Dudley in the West Midlands. The engine was relatively inefficient and in most cases was used for pumping water. It was employed for draining mine workings at depths previously impossible, and also for providing a reusable water supply for driving waterwheels at factories sited away from a suitable “head.” Water that had passed over the wheel was pumped back up into a storage reservoir above the wheel.

Diagram of the Newcomen steam engine, Henry Black Newton and Harvey Nathaniel Davis, Practical physics for secondary schools. Fundamental principles and applications to daily life, Macmillan and Company, 1913, p. 219.

The Newcomen engine operated by condensing steam drawn into the cylinder, thereby creating a partial vacuum and allowing the atmospheric pressure to push the piston into the cylinder. It was the first practical device to harness steam to produce mechanical work.

Newcomen’s engine held its place without material change for about 75 years, spreading gradually to more areas of the UK and mainland Europe. At first brass cylinders were used, but these were expensive and limited in size. New iron casting techniques pioneered by the Coalbrookdale Company in the 1720s allowed bigger cylinders to be used, up to about 6 feet (1.8 m) in diameter by the 1760s. Experience led to better construction and minor refinements in layout. Its mechanical details were much improved by John Smeaton, who built many large engines of this type in the early 1770s, and his improvements were rapidly adopted. By 1775, about 600 Newcomen engines had been built.

Boulton and Watt

The Boulton and Watt steam engine led to replacing the water wheel and horses as the main sources of power for British industry, thereby freeing it from geographical constraints and becoming one of the main drivers in the Industrial Revolution.

Learning Objectives

Recognize why Boulton and Watt’s steam engine achieved widespread success

Key Takeaways

Key Points

- In 1763, James Watt, an instrument maker at the University of Glasgow, was assigned the job of repairing a model Newcomen engine (based on an earlier design of the Savery engine) and noted how inefficient it was. In 1765, Watt conceived the idea of equipping the engine with a separate condensation chamber, which he called a condenser. Because the condenser and the working cylinder were separate, condensation occurred without significant loss of heat from the cylinder. This invention dramatically improved the efficiency of the engine.

- Watt’s next improvement to the Newcomen design was to seal the top of the cylinder and surround the cylinder with a jacket. Steam was passed through the jacket before being admitted below the piston, keeping the piston and cylinder warm to prevent condensation within it. These improvements led to the fully developed version of 1776 that actually went into production.

- The separate condenser showed dramatic potential for improvements on the Newcomen engine, but Watt was still discouraged by seemingly insurmountable problems before a marketable engine could be perfected. It was only after entering into partnership with Matthew Boulton that this became reality. Boulton and Watt became an engineering company that was critical to the technological advancements of the Industrial Revolution.

- As fully developed, the Watt engine used about 75% less fuel than a similar Newcomen one. Boulton and Watt’s practice was to help mine owners and other customers build engines, supplying men to erect them and specialized parts. However, their main profit from their patent was derived from charging a licence fee to the engine owners based on the cost of the fuel they saved. The greater fuel efficiency of their engines meant that they were most attractive in areas where fuel was expensive.

- Later improvements introduced by Watt included an arrangement of valves that could alternately admit low pressure steam to the cylinder and connect with the condenser (the double acting piston); parallel motion; transforming the action of the beam into a rotating motion (first by the epicyclic sun and planet gear system suggested by an employee William Murdoch and later by connecting the beam to a wheel by a crank after patent rights on the use of the crank expired), and linking a steam regulator valve to a centrifugal governor to keep a constant speed.

- These improvements allowed the steam engine to replace the water wheel and horses as the main sources of power for British industry, thereby freeing it from geographical constraints and allowing it to become one of the main drivers in the Industrial Revolution.

Key Terms

- reciprocating engine: A heat engine also known as a piston engine that uses one or more reciprocating pistons to convert pressure into a rotating motion. The main types are the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the niche application Stirling engine.

- parallel motion: A mechanical linkage invented by the Scottish engineer James Watt in 1784 for the double-acting Watt steam engine. It allows a rod moving straight up and down to transmit motion to a beam moving in an arc, without putting sideways strain on the rod.

- Boulton and Watt: An early British engineering and manufacturing firm in the business of designing and making marine and stationary steam engines. Founded in the English West Midlands around Birmingham in 1775 as a partnership between the English manufacturer Matthew Boulton and the Scottish engineer James Watt, the firm had a major role in the Industrial Revolution and grew to be a major producer of steam engines in the 19th century.

- condenser: A device or unit used to condense a substance from its gaseous to its liquid state by cooling it, which transfers the latent heat from the substance to the condenser coolant. These devices are typically heat exchangers, which have various designs and come in many sizes ranging from rather small (hand-held) to very large industrial-scale units used in plant processes.

- atmospheric engine: An engine invented by Thomas Newcomen in 1712, often referred to simply as a Newcomen engine. The engine operated by condensing steam drawn into the cylinder, thereby creating a partial vacuum and allowing the atmospheric pressure to push the piston into the cylinder. It was the first practical device to harness steam to produce mechanical work.

James Watt: Improving the Newcomen Engine

In 1698, English mechanical designer Thomas Savery invented a pumping appliance that used steam to draw water directly from a well by means of a vacuum created by condensing steam. The appliance was also proposed for draining mines, but could only draw fluid up approximately 25 feet, meaning it had to be located within this distance of the mine floor. As mines became deeper, this was often impractical. The solution to draining deep mines was found by Thomas Newcomen, who developed an atmospheric engine that also worked on the vacuum principle. The Newcomen engine was more powerful than the Savery engine. For the first time, water could be raised from a depth of over 150 feet. However, while Newcomen engines brought practical benefits, they were inefficient in terms of energy use. The system of alternately sending jets of steam then cold water into the cylinder meant that the walls of the cylinder were alternately heated then cooled with each stroke. Each charge of steam introduced would continue condensing until the cylinder approached working temperature again, so at each stroke part of the potential of the steam was lost.

In 1763, James Watt was working as instrument maker at the University of Glasgow when he was assigned the job of repairing a model Newcomen engine and noted how inefficient it was. In 1765, Watt conceived the idea of equipping the engine with a separate condensation chamber, which he called a condenser. Because the condenser and the working cylinder were separate, condensation occurred without significant loss of heat from the cylinder. The condenser remained cold and below atmospheric pressure at all times, while the cylinder remained hot at all times. Steam was drawn from the boiler to the cylinder under the piston. When the piston reached the top of the cylinder, the steam inlet valve closed and the valve controlling the passage to the condenser opened. The lower pressure of the condenser, drew the steam into the cylinder where it cooled and condensed from water vapor to liquid water, maintaining a partial vacuum in the condenser that was communicated to the space of the cylinder by the connecting passage. External atmospheric pressure then pushed the piston down the cylinder.

The separation of the cylinder and condenser eliminated the loss of heat that occurred when steam was condensed in the working cylinder of a Newcomen engine. This gave the Watt engine greater efficiency than the Newcomen engine, reducing the amount of coal consumed while doing the same amount of work. In Watt’s design, the cold water was injected only into the condensation chamber. This type of condenser is known as a jet condenser.

Watt’s next improvement to the Newcomen design was to seal the top of the cylinder and surround it with a jacket. Steam was passed through the jacket before being admitted below the piston, keeping the piston and cylinder warm to prevent condensation within it. Watt did not use high-pressure steam because of safety concerns, although he was aware of its potential and included expansive working knowledge in his patent of 1782. These improvements led to the fully developed version of 1776 that actually went into production.

Boulton and Watt Join Forces

The separate condenser showed dramatic potential for improvements on the Newcomen engine but Watt was still discouraged by seemingly insurmountable problems before a marketable engine could be perfected. It was only after entering into partnership with Matthew Boulton that this became reality. Watt told Boulton about his ideas on improving the engine and Boulton, an avid entrepreneur, agreed to fund development of a test engine at Soho, near Birmingham. At last Watt had access to facilities and the practical experience of craftsmen who were soon able to get the first engine working. As fully developed, it used about 75% less fuel than a similar Newcomen model.

The major components of a Watt pumping engine, Robert H. Thurston, History of the Growth of the Steam Engine, D. Appleton & Co, 1878.

The Boulton and Watt steam engine (known also as the Watt engine), developed sporadically from 1763 to 1775, was an improvement on the design of the Newcomen engine and was a key point in the Industrial Revolution.

In 1775, Watt designed two large engines: one for the Bloomfield Colliery at Tipton and one for John Wilkinson’s ironworks at Willey, Shropshire, both completed in 1776. A third engine, at Stratford-le-Bow in east London, was also working that year. Boulton and Watt’s practice was to help mine owners and other customers build engines, supplying men to erect them and specialized parts. However, the main profit from their patent was derived from charging a license fee to the engine owners, based on the cost of the fuel they saved. The greater fuel efficiency of their engines meant that they were most attractive in areas where fuel was expensive, particularly Cornwall, for which three engines were ordered in 1777.

Later Improvements

The first Watt engines were atmospheric pressure engines, like the Newcomen engine but with the condensation separated from the cylinder. Driving the engines using both low pressure steam and a partial vacuum raised the possibility of reciprocating engine development. An arrangement of valves could alternately admit low-pressure steam to the cylinder and connect with the condenser. Consequently, the direction of the power stroke might be reversed, making it easier to obtain rotary motion. Additional benefits of the double-acting engine were increased efficiency, higher speed (greater power), and more regular motion.

Before the development of the double-acting piston, e to the beam and the piston rod were linked by a chain, which meant that power could only be applied in one direction, by pulling. This was effective in engines used for pumping water, but the double action of the piston meant that it could push as well as pull. Further, it was not possible to connect the piston rod of the sealed cylinder directly to the beam, because while the rod moved vertically in a straight line, the beam was pivoted at its center with each side inscribing an arc. To bridge the conflicting actions of the beam and the piston, Watt developed his parallel motion. This masterpiece of engineering uses a four-bar linkage coupled with a pantograph (a type of current collector) to produce the required straight-line motion much more cheaply than if he had used a slider type of linkage. He was very proud of his solution.

Watt’s parallel motion on a pumping engine

In a letter to his son in 1808, James Watt wrote, “I am more proud of the parallel motion than of any other invention I have ever made.” The sketch he included actually shows what is now known as Watt’s linkage, which was described in Watt’s 1784 patent but was immediately superseded by the parallel motion. The parallel motion differed from Watt’s linkage by having an additional pantograph linkage incorporated in the design. This did not affect the fundamental principle but it allowed the engine room to be smaller because the linkage was more compact.

Having the beam connected to the piston shaft by a means that applied force alternately in both directions also meant that the motion of the beam could be used to turn a wheel. The simplest solution to transforming the action of the beam into a rotating motion was to connect the beam to a wheel by a crank, but because another party had patent rights on the use of the crank, Watt was obliged to come up with another solution. He adopted the epicyclic sun and planet gear system suggested by employee William Murdoch, only later reverting, once the patent rights had expired, to the more familiar crank seen on most engines today. The main wheel attached to the crank was large and heavy, serving as a flywheel that once set in motion, by its momentum maintained a constant power and smoothed the action of the alternating strokes. To its rotating central shaft, belts and gears could be attached to drive a great variety of machinery. Because factory machinery needed to operate at a constant speed, Watt linked a steam regulator valve to a centrifugal governor, which he adapted from those used to automatically control the speed of windmills.

These improvements allowed the steam engine to replace the water wheel and horses as the main sources of power for British industry, thereby freeing it from geographical constraints and becoming one of the main drivers in the Industrial Revolution. Watt was also concerned with fundamental research on the functioning of the steam engine. His most notable measuring device, still in use today, is the Watt indicator, incorporating a manometer to measure steam pressure within the cylinder according to the position of the piston. This enabled a diagram to be produced representing the pressure of the steam as a function of its volume throughout the cycle.

The Spread of Steam Power

Steam engines found many uses in a variety of industries, most notably mining and transportation, but its popularization shaped nearly every aspect of the industrial society, including where people could live, labor, and travel; how goods were produced, marketed, and sold; and what technological innovations followed.

Learning Objectives

Give examples of the industries powered by steam

Key Takeaways

Key Points

- The steam engine was one of the most important technologies of the Industrial Revolution, inspiring other innovations and initiating further technological advancements. In 1775, James Watt formed an engine building and engineering partnership with manufacturer Matthew Boulton. This served as a kind of creative technical center for much of the British economy. They supported talents and other companies, creating a culture where firms often shared information that they could use to create new techniques or products.

- From mines to mills, steam engines found many uses in a variety of industries. The introduction of steam engines improved productivity and technology and allowed the creation of smaller and better engines. Around the start of the 19th century, Cornish engineer Richard Trevithick and American Oliver Evans began to construct higher-pressure non-condensing steam engines, exhausting against the atmosphere. After Trevithick’s development, transport applications became possible and steam engines found their way into boats, railways, farms, and road vehicles.

- The steam engine was originally invented and perfected to be used in mines. The introduction of the steam pump by Savery in 1698 and the Newcomen steam engine in 1712 greatly facilitated the removal of water and enabled shafts to be made deeper, enabling more coal to be extracted. The adoption of John Smeaton’s improvements to the Newcomen engine followed by James Watt’s more efficient steam engines from the 1770s reduced the fuel costs of engines, making mines more profitable.

- Steam locomotives were invented after the introduction of high pressure steam engines when the Boulton and Watt patent expired in 1800. Steam-hauled public railways began with the Stockton and Darlington Railway in 1825. The use of steam engines on railroads proved extraordinary since large amounts of goods and raw materials could now be delivered to cities and factories alike at a fraction of the cost traveling by wagon.

- Following the advent of the steamboat, the United States saw an incredible growth in the transportation of goods and people, which was key in westward expansion. The steamboat dramatically reduced time used to transport goods and allowed for increased specialization. The steamboat was also critical to facilitating the internal slave trade. With the steamboat came the need for an improved river system and infrastructure along the rivers.

- Steam engines are a particularly illustrative example of how changes brought by industrialization led to even more changes in other areas. While many consider the potential for an increase in power generated the dominant benefit, others favor the potential for agglomeration. Steam engines made it possible to easily work, live, produce, market, specialize, and viably expand without having to worry about the less abundant presence of waterways.

Key Terms

- Boulton and Watt: An early British engineering and manufacturing firm in the business of designing and making marine and stationary steam engines. Founded in the English West Midlands around Birmingham in 1775 as a partnership between the English manufacturer Matthew Boulton and the Scottish engineer James Watt, the firm had a major role in the Industrial Revolution and grew to be a major producer of steam engines in the 19th century.

- steam engine: A heat engine that performs mechanical work using steam as its working fluid.

- beam engine: A type of steam engine where a pivoted overhead beam is used to apply the force from a vertical piston to a vertical connecting rod. This configuration, with the engine directly driving a pump, was first used by Thomas Newcomen around 1705 to remove water from mines in Cornwall.

Steam Engine Revolution

The steam engine was one of the most important technologies of the Industrial Revolution, although steam did not replace water power in importance in Britain until after the Industrial Revolution. From Englishmen Thomas Savery’s first practical, atmospheric pressure engine (1698) and Thomas Newcomen’s atmospheric engine (1712) through major developments by Scottish inventor and mechanical engineer James Watt, the steam engine became used in many industrial settings. In 1775, Watt formed an engine-building and engineering partnership with manufacturer Matthew Boulton that became one of the most important businesses of the Industrial Revolution and served as a creative technical center for much of the British economy. The partners solved technical problems and spread the solutions to other companies. Similar firms did the same thing in other industries and were especially important in the machine tool industry. These interactions between companies reduced the amount of research time and expense that each business had to spend working with its own resources. The technological advances of the Industrial Revolution happened more quickly because firms often shared information they could use to create new techniques or products.

Watt’s rotative engine at the Henry Ford Museum: The Henry Ford Museum in Dearborn, Michigan houses a Watt rotative engine manufactured in 1788 by Charles Summerfield. This is a full-scale working Boulton-Watt engine. The American industrialist Henry Ford moved the engine to Dearborn around 1930.

Major Applications

From mines to mills, steam engines found many uses in a variety of industries. The introduction of steam engines improved productivity and technology and allowed the creation of smaller and better engines. Until about 1800, the most common type of steam engine was the beam engine, built as an integral part of a stone or brick engine-house, but soon various patterns of self-contained rotative engines (readily removable, but not on wheels) were developed, such as the table engine. Around the start of the 19th century, the Cornish engineer Richard Trevithick and American Oliver Evans began to construct higher-pressure non-condensing steam engines, exhausting against the atmosphere. After Trevithick’s development, transport applications became possible and steam engines found their way into boats, railways, farms, and road vehicles.

The steam engine was originally invented and perfected to be used in mines. Before the steam engine, shallow bell pits followed a seam of coal along the surface and were abandoned as the coal was extracted. In other cases, if the geology was favorable, the coal was mined by a drift mine driven into the side of a hill. Shaft mining was done in some areas, but the limiting factor was the problem of removing water. It could be done by hauling buckets of water up the shaft or to a tunnel driven into a hill t. In either case, the water had to be discharged into a stream or ditch at a level where it could flow away by gravity. The introduction of the steam pump by Savery in 1698 and the Newcomen steam engine in 1712 greatly facilitated the removal of water and enabled shafts to be made deeper, enabling more coal to be extracted. These developments began before the Industrial Revolution, but the adoption of John Smeaton’s improvements to the Newcomen engine followed by James Watt’s more efficient steam engines from the 1770s reduced the fuel costs of engines, making mines more profitable.

At the beginning of the Industrial Revolution, inland transport was by navigable rivers and roads, with coastal vessels employed to move heavy goods by sea. Wagon ways were used for conveying coal to rivers for further shipment, but canals had not yet been widely constructed. Animals supplied all of the motive power on land, with sails providing the motive power on the sea. The first horse railways were introduced toward the end of the 18th century, with steam locomotives introduced in the early decades of the 19th century. Steam locomotives were invented after the introduction of high-pressure steam engines when the Boulton and Watt patent expired in 1800. High-pressure engines exhausted used steam to the atmosphere, doing away with the condenser and cooling water. A few of these early locomotives were used in mines. Steam-hauled public railways began with the Stockton and Darlington Railway in 1825. The use of steam engines on railroads proved extraordinary in the fact that now you could have large amounts of goods and raw materials delivered to cities and factories alike. Trains could deliver these to places far away at a fraction of the cost traveling by wagon.

Particularly in the United States, the introduction and development of the steamboat resulted in vast changes. Prior to the steamboat, rivers were generally only used in transporting goods from east to west, and from north to south as fighting the current was very difficult and often impossible. Non-powered boats and rafts were assembled upstream to carry cargo downstream, and would often be disassembled at the end of their journey and the remains used to construct homes and commercial buildings. Following the advent of the steamboat, the U.S. saw incredible growth in the transportation of goods and people, which was key in westward expansion. The steamboat dramatically reduced time used to transport goods and allowed for increased specialization. It was also critical to facilitating the internal slave trade.

With the steamboat came the need for an improved river system. The natural river system produced such obstacles as rapids, sand bars, shallow waters, and waterfalls. To overcome these natural obstacles, a network of canals, locks, and dams was constructed. This increased demand for labor along the rivers, resulting in tremendous job growth. The popularization of the steamboat also led directly to growth in the coal and insurance industries and demand for repair facilities along the rivers. Additionally, the demand for goods in general increased as the steamboat made transport to new destinations both wide-reaching and efficient.

1920 Steamboat on the Yukon River near Whitehorse, Frank G Carpenter Collection, US Library of Congress.

Prior to the steamboat, it could take between three and four months to make the passage from New Orleans to Louisville, averaging twenty miles a day. With the steamboat this time was reduced drastically with trips ranging from twenty-five to thirty-five days. This was especially beneficial to farmers as their crops could now be transported elsewhere to be sold.

Steam Engine and Societal Progress

Steam engines are a particularly illustrative example of how changes brought by industrialization led to even more changes in other area. Water power, the world’s preceding supply of power, continued to be an essential source even during the height of steam engine popularity. The steam engine, however, provided many novel benefits. While many consider the potential for an increase in power generated o be the dominant benefit (with the average horsepower of steam powered mills producing four times the power of water powered mills), others favor the potential for agglomeration. Steam engines made it possible to easily work, live, produce, market, specialize, and viably expand without having to worry about the less abundant presence of waterways. Cities and towns were now built around factories, where steam engines served as the foundation for the livelihood of many of the citizens. By promoting the agglomeration of individuals, successful local markets were established. Cities quickly grew and the quality of living eventually increased as infrastructure was put in place. Finer goods could be produced as acquisition of materials became less difficult and expensive. Direct local competition led to higher degrees of specialization and labor and capital were in rich supply. The steam-powered towns encouraged growth both locally and on the national scale.

Candela Citations

- Aeolipile. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Aeolipile. License: CC BY-SA: Attribution-ShareAlike

- Steam power during the Industrial Revolution. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Steam_power_during_the_Industrial_Revolution. License: CC BY-SA: Attribution-ShareAlike

- Newcomen atmospheric engine. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Newcomen_atmospheric_engine. License: CC BY-SA: Attribution-ShareAlike

- Beam engine. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Beam_engine. License: CC BY-SA: Attribution-ShareAlike

- Thomas Savery. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Thomas_Savery. License: CC BY-SA: Attribution-ShareAlike

- Steam engine. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Steam_engine. License: CC BY-SA: Attribution-ShareAlike

- Thomas Newcomen. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Thomas_Newcomen. License: CC BY-SA: Attribution-ShareAlike

- Savery-engine.jpg. Provided by: Wikimedia Commons. Located at: https://commons.wikimedia.org/wiki/File:Savery-engine.jpg. License: Public Domain: No Known Copyright

- 800px-Newcomen6325.png. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Newcomen_atmospheric_engine#/media/File:Newcomen6325.png. License: Public Domain: No Known Copyright

- Parallel motion. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Parallel_motion. License: CC BY-SA: Attribution-ShareAlike

- Boulton and Watt. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Boulton_and_Watt. License: CC BY-SA: Attribution-ShareAlike

- Industrial Revolution. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Industrial_Revolution. License: CC BY-SA: Attribution-ShareAlike

- Reciprocating engine. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Reciprocating_engine. License: CC BY-SA: Attribution-ShareAlike

- Condenser (heat transfer). Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Condenser_(heat_transfer). License: CC BY-SA: Attribution-ShareAlike

- Newcomen atmospheric engine. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Newcomen_atmospheric_engine. License: CC BY-SA: Attribution-ShareAlike

- Pantograph (transport). Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Pantograph_(transport). License: CC BY-SA: Attribution-ShareAlike

- Watt steam engine. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Watt_steam_engine. License: CC BY-SA: Attribution-ShareAlike

- Steam engine. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Steam_engine. License: CC BY-SA: Attribution-ShareAlike

- Savery-engine.jpg. Provided by: Wikimedia Commons. Located at: https://commons.wikimedia.org/wiki/File:Savery-engine.jpg. License: Public Domain: No Known Copyright

- 800px-Newcomen6325.png. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Newcomen_atmospheric_engine#/media/File:Newcomen6325.png. License: Public Domain: No Known Copyright

- 800px-WattParallelMotion.jpg. Provided by: Wikimedia Commons. Located at: https://commons.wikimedia.org/wiki/File:WattParallelMotion.jpg. License: Public Domain: No Known Copyright

- 800px-Watt_steam_pumping_engine.JPG. Provided by: Wikimedia Commons. Located at: https://commons.wikimedia.org/wiki/File:Watt_steam_pumping_engine.JPG. License: Public Domain: No Known Copyright

- Watt steam engine. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Watt_steam_engine. License: CC BY-SA: Attribution-ShareAlike

- Industrial Revolution . Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Industrial_Revolution. License: CC BY-SA: Attribution-ShareAlike

- Boulton and Watt. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Boulton_and_Watt. License: CC BY-SA: Attribution-ShareAlike

- Steam engine. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Steam_engine. License: CC BY-SA: Attribution-ShareAlike

- Beam engine. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Beam_engine. License: CC BY-SA: Attribution-ShareAlike

- Steam power during the Industrial Revolution. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Steam_power_during_the_Industrial_Revolution. License: CC BY-SA: Attribution-ShareAlike

- Savery-engine.jpg. Provided by: Wikimedia Commons. Located at: https://commons.wikimedia.org/wiki/File:Savery-engine.jpg. License: Public Domain: No Known Copyright

- 800px-Newcomen6325.png. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Newcomen_atmospheric_engine#/media/File:Newcomen6325.png. License: Public Domain: No Known Copyright

- 800px-WattParallelMotion.jpg. Provided by: Wikimedia Commons. Located at: https://commons.wikimedia.org/wiki/File:WattParallelMotion.jpg. License: Public Domain: No Known Copyright

- 800px-Watt_steam_pumping_engine.JPG. Provided by: Wikimedia Commons. Located at: https://commons.wikimedia.org/wiki/File:Watt_steam_pumping_engine.JPG. License: Public Domain: No Known Copyright

- 15_23_1056_ford_museum.jpg. Provided by: Wikimedia Commons. Located at: https://commons.wikimedia.org/wiki/File:15_23_1056_ford_museum.jpg. License: Public Domain: No Known Copyright

- 800px-1920_Steamboat_on_the_Yukon_River.jpg. Provided by: Wikipedia. Located at: https://en.wikipedia.org/wiki/Steam_power_during_the_Industrial_Revolution#/media/File:1920_Steamboat_on_the_Yukon_River.jpg. License: Public Domain: No Known Copyright