Indian Institute of Technology: Professor Arun Kanda’s “Forecasting”

Watch this lecture for a detailed look at the importance of forecasting in identifying capacity requirements. Professor Kanda also reviews a variety of forecasting models along with the process of forecast control.

10.5 Forecasting Demand

Learning Objective

- Forecast demand for a product.

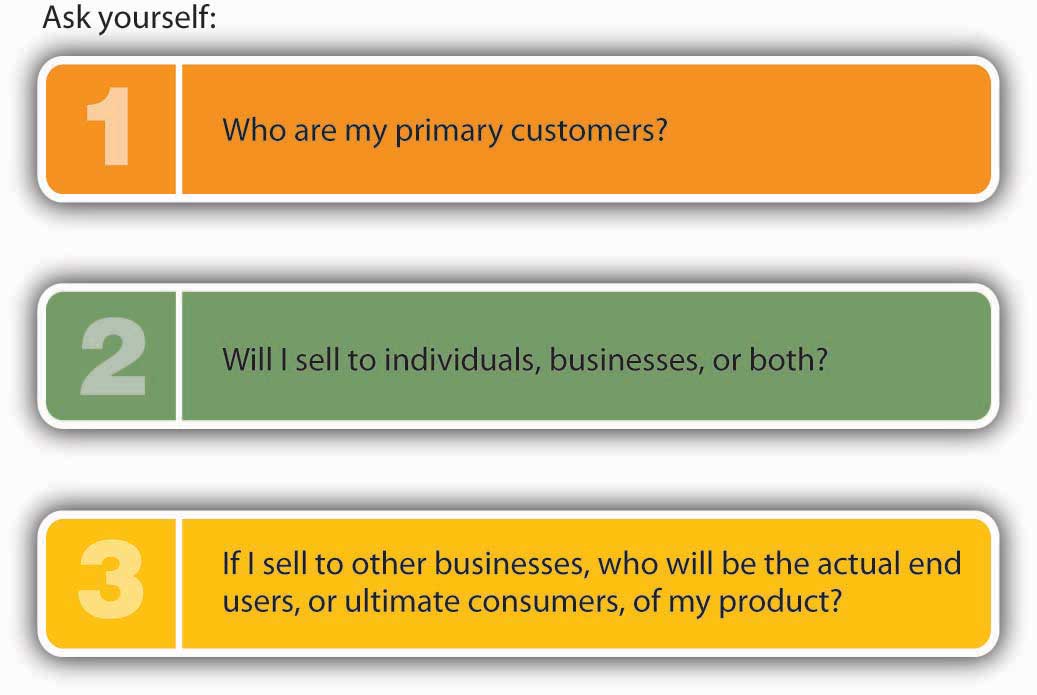

It goes without saying, but we’ll say it anyway: without enough customers, your business will go nowhere. So, before you delve into the complex, expensive world of developing and marketing a new product, ask yourself questions like those in Figure 10.5 “When to Develop and Market a New Product”. When Bob Montgomery asked himself these questions, he concluded that he had two groups of customers for the PowerSki Jetboard: (1) the dealerships that would sell the product and (2) the water-sports enthusiasts who would buy and use it. His job, therefore, was to design a product that dealers would want to sell and enthusiasts would buy. When he was confident that he could satisfy these criteria, he moved forward with his plans to develop the PowerSki Jetboard.

Figure 10.5 When to Develop and Market a New Product

After you’ve identified a group of potential customers, your next step is finding out as much as you can about what they think of your product idea. Remember: because your ultimate goal is to roll out a product that satisfies customer needs, you need to know ahead of time what your potential customers want. Precisely what are their unmet needs? Ask them questions such as these:Karl Ulrich and Steven Eppinger, Product Design and Development, 2nd ed. (New York: Irwin McGraw-Hill, 2000), 66; and Kathleen Allen, Entrepreneurship for Dummies (Foster, CA: IDG Books, 2001), 79.

- What do you like about this product idea? What don’t you like?

- What improvements would you make?

- What benefits would you get from it?

- Would you buy it? Why, or why not?

- What would it take for you to buy it?

Before making a substantial investment in the development of a product, you need to ask yourself yet another question: are there enough customers willing to buy my product at a price that will allow me to make a profit? Answering this question means performing one of the hardest tasks in business: forecasting demand for your proposed product. There are several possible approaches to this task that can be used alone or in combination.

People in Similar Businesses

Though some businesspeople are reluctant to share proprietary information, such as sales volume, others are willing to help out individuals starting new businesses or launching new products. Talking to people in your prospective industry (or one that’s similar) can be especially helpful if your proposed product is a service. Say, for example, that you plan to open a pizza parlor with a soap opera theme: customers will be able to eat pizza while watching reruns of their favorite soap operas on personal TV/DVD sets. If you visited a few local restaurants and asked owners how many customers they served every day, you’d probably learn enough to estimate the number of pizzas that you’d serve during your first year. If the owners weren’t cooperative, you could just hang out and make an informal count of the customers.

Potential Customers

You can also learn a lot by talking with potential customers. Ask them how often they buy products similar to the one you want to launch. Where do they buy them and in what quantity? What factors affect demand for them? If you were contemplating a frozen yogurt store in Michigan, it wouldn’t hurt to ask customers coming out of a bakery whether they’d buy frozen yogurt in the winter.

Published Industry Data

To get some idea of the total market for products like the one you want to launch, you might begin by examining pertinent industry research. For example, to estimate demand for jogging shoes among consumers sixty-five and older, you could look at data published on the industry association’s Web site, National Sporting Goods Association, http://www.nsga.org/i4a/pages/index.cfm?pageid=1.“Running USA: Running Defies The Great Recession, Running USA’s State of the Sport 2010—Part II,” LetsRun.com, http://www.letsrun.com/2010/recessionproofrunning0617.php (accessed October 28, 2011); “Sporting Goods Market in 2010,” National Sporting Goods Association, http://www.nsga.org/i4a/pages/index.cfm?pageid=1 (accessed October 28, 2011). Here you’d find that forty million jogging/running shoes were sold in the United States in 2008 at an average price of $58 per pair. The Web site also reports that the number of athletes who are at least forty and who participate in road events increased by more than 50 percent over a ten year period.“Long Distance Running: State of the Sport,” USA Track & Field, http://www.usatf.org/news/specialReports/2003LDRStateOfTheSport.asp (accessed October 29, 2011). To find more specific information—say, the number of joggers older than sixty-five—you could call or e-mail USA Track and Field. You might find this information in an eighty-seven-page statistical study of retail sporting-goods sales published by the National Sporting Goods Association.National Sporting Goods Association, http://nsga.org (accessed October 28, 2011). If you still don’t get a useful answer, try contacting organizations that sell industry data. American Sports Data, for instance, provides demographic information on no fewer than twenty-eight fitness activities, including jogging.“Trends in U.S. Physical Fitness Behavior (1987–Present),” http://www.americansportsdata.com/phys_fitness_trends1.asp (accessed October 28, 2011). You’d want to ask them for data on the number of joggers older than sixty-five living in Florida. There’s a lot of valuable and available industry-related information that you can use to estimate demand for your product.

Now, let’s say that your research turns up the fact that there are three million joggers older than sixty-five and that six hundred thousand of them live in Florida, which attracts 20 percent of all people who move when they retire.Alan Scher Zagier, “Eyeing Competition, Florida Increases Efforts to Lure Retirees,” Boston Globe, December 26, 2003, http://www.boston.com/news/nation/articles/2003/12/26/eyeing_competition_florida_increases_efforts_to_lure_retirees (accessed October 28, 2011). How do you use this information to estimate the number of jogging shoes that you’ll be able to sell during your first year of business? First, you have to estimate your market share: your portion of total sales in the older-than-sixty-five jogging shoe market in Florida. Being realistic (but having faith in an excellent product), you estimate that you’ll capture 2 percent of the market during your first year. So you do the math: 600,000 pairs of jogging shoes sold in Florida × 0.02 (a 2 percent share of the market) = 12,000, the estimated first-year demand for your proposed product.

Granted, this is just an estimate. But at least it’s an educated guess rather than a wild one. You’ll still want to talk with people in the industry, as well as potential customers, to hear their views on the demand for your product. Only then would you use your sales estimate to make financial projections and decide whether your proposed business is financially feasible. We’ll discuss this process in a later chapter.

Key Takeaways

- After you’ve identified a group of potential customers, your next step is finding out as much as you can about what they think of your product idea.

- Before making a substantial investment in the development of a product, you need to ask yourself: are there enough customers willing to buy my product at a price that will allow me to make a profit?

- Answering this question means performing one of the hardest tasks in business: forecasting demand for your proposed product.

- There are several possible approaches to this task that can be used alone or in combination.

- You can obtain helpful information about product demand by talking with people in similar businesses and potential customers.

- You can also examine published industry data to estimate the total market for products like yours and estimate your market share, or portion of the targeted market.

Exercise

(AACSB) Analysis

Your friends say you make the best pizzas they’ve ever eaten, and they’re constantly encouraging you to set up a pizza business in your city. You have located a small storefront in a busy section of town. It doesn’t have space for an eat-in restaurant, but it will allow customers to pick up their pizzas. You will also deliver pizzas. Before you sign a lease and start the business, you need to estimate the number of pizzas you will sell in your first year. At this point you plan to offer pizza in only one size.

Before arriving at an estimate, answer these questions:

- What factors would you consider in estimating pizza sales?

- What assumptions will you use in estimating sales (for example, the hours your pizza shop will be open)?

- Where would you obtain needed information to calculate an estimate?

Then, estimate the number of pizzas you will sell in your first year of operations.

ids355: Operations Management Wikispace: “Chapter 5: Strategic Capacity Planning for Products and Services”

Read the chapter five summary. Pay attention to the inputs to capacity planning and the determinants and steps in the capacity planning process. This is important to understanding how to use this information to increase the quality of your forecasts. In addition, this helps you understand your organization’s capability to meet the forecast needs. Answer the questions at the end of the summary. Compare your results with the authors.

Ch. 5 Strategic Capacity Planning for Products and Services

Chapter 5

This chapter examines how important strategic capacity planning is for products and services. The overall objective of strategic capacity planning is to reach an optimal level where production capabilities meet demand. Capacity needs include equipment, space, and employee skills. If production capabilities are not meeting demand, high costs, strains on resources, and customer loss may result. It is important to note that capacity planning has many long term concerns given the long term commitment of resources.

Managers should recognize the broader effects capacity decisions have on the entire organization. Common strategies include leading capacity, where capacity is increased to meet expected demand, and following capacity, where companies wait for demand increases before expanding capabilities. A third approach is tracking capacity which adds incremental capacity over time to meet demand.

Finally, The two most useful functions of capacity planning are design capacity and effective capacity. Design capacity refers to the maximum designed service capacity or output rate and the effective capacity is the design capacity minus personal and other allowances. These two functions of capacity can be used to find the efficiency and utilization. These are calculated by the formulas below:

Efficiency = Actual Output/ Effective Capacity x 100%

Utilization = Actual Output/ Design Capacity x 100%

—

Chapter 5 Strategic Capacity Planning for Products and Services

Capacity refers to a system’s potential for producing goods or delivering services over a specified time interval. Capacity planning involves long-term and short term considerations. Long-term considerations relate to the overall level of capacity; short-term considerations relate to variations in capacity requirements due to seasonal, random, and irregular fluctuations in demand.

Excess capacity arises when actual production is less than what is achievable or optimal for a firm. This often means that the demand in the market for the product is below what the firm could potentially supply to the market. Excess capacity is inefficient and will cause manufacturers to incur extra costs or lose market share. Capacity can be broken down in two categories: Design Capacity and Effective Capacity: refers to the maximum designed service capacity or output rate. Effective capacity is design capacity minus personal and other allowances. Product and service factors effect capacity tremendously.

Chapter 5 focuses on capacity planning for products and services. Capacity is the ability of a systems potential for producing goods or delivering services over a specific time interval. The capacity decisions within a company are very important because they help determine the limit of output and provide a major insight to determining operating costs. Basic decisions about capacity often have long term consequences and this chapter explains the ramifications of those choices. When considering capacity planning within a company, three key inputs should be considered. The three inputs are the kind of capacity to be determined, how much of the products will be needed, and when will the product be needed.

The most important concept of capacity planning is to find a medium between long term supply and capabilities of an organization and the predicted level of long term demand. Organizations also have to plan for actual changes in capacity, changes in consumer wants and demand, technology and even the environment. When evaluating alternatives in capacity planning, managers have to consider qualitative and quantitative aspects of the business. These aspects involve economic factors, public opinions, personal preferences of managers.

This chapter describes capacity planning as a key factor in designing systems. The capacity decision is strategic and long-term in nature. Capacity planning is described as matching the capabilities of an organization with the predicted level of future demand. Many organizations become involved with capacity planning due to changes in demand, technology, the environment, etc. Organizations have capacities or limits that their system can handle.

Three key inputs to capacity planning:

1. The kind of capacity that will be needed

2. How much capacity will be needed

3. When will it be needed

*Accurate forecasts are critical to the planning process

Defining And Measuring Capacity

When selecting a measure of capacity, it is best to choose one that doesn’t need updating. When dealing with more than one product, it is best to measure capacity in terms of each product. For example, the capacity of a firm is to either produce 100 microwaves or 75 refrigerators. This is less confusing than just saying the capacity is 100 or 75. Another method of

measuring capacity is by referring to the availability of inputs. Note that one specific measure of capacity can’t be used in all situations; it needs to tailored to the specific situation at hand.

Determinants of Effective Capacity

- Facilities: The size and provision for expansion are key in the design of facilities. Other facility factors include locational factors (transportation costs, distance to market, labor supply, energy sources). The layout of the work area can determine how smoothly work can be performed.

- Product and Service Factors: The more uniform the output, the more opportunities there are for standardization of methods and materials. This leads to greater capacity.

- Process Factors: Quantity capability is an important determinant of capacity, but so is output quality. If the quality does not meet standards, then output rate decreases because of need of inspection and rework activities. Process improvements that increase quality and productivity can result in increased capacity. Another process factor to consider is the time it takes to change over equipment settings for different products or services.

- Human Factors: the tasks that are needed in certain jobs, the array of activities involved and the training, skill, and experience required to perform a job all affect the potential and actual output. Employee motivation, absenteeism, and labor turnover all affect the output rate as well.

- Policy Factors: Management policy can affect capacity by allowing or not allowing capacity options such as overtime or second or third shifts

- Operational Factors: Scheduling problems may occur when an organization has differences in equipment capabilities among different pieces of equipment or differences in job requirements. Other areas of impact on effective capacity include inventory stocking decisions, late deliveries, purchasing requirements, acceptability of purchased materials and parts, and quality inspection and control procedures.

- Supply Chain Factors: Questions include: What impact will the changes have on suppliers, warehousing, transportation, and distributors? If capacity will be increased, will these elements of the supply chain be able to handle the increase? If capacity is to be decreased, what impact will the loss of business have on these elements of the supply chain?

- External Factors: Minimum quality and performance standards can restrict management’s options for increasing and using capacity.

- Inadequate planning can be a major limiting determining of effective capacity.

The most important parts of effective capacity are process and human factors. Process factors must be efficient and must operate smoothly, if not the rate of output will dramatically decrease. Human factors must be trained well and have experience, they must be motivated and have a low absenteeism and labor turnover. In resolving constraint issues, all possible alternative solutions must be evaluated. This is possible by using CVP analysis and the Break-Even Point formula.

Steps in the Capacity Planning Process

1. Estimate future capacity requirements

2. Evaluate existing capacity and facilities and identify gaps

3. Identify alternatives for meeting requirements

4. Conduct financial analyses of each alternative

5. Assess key qualitative issues for each alternative

6. Select the alternative to pursue that will be best in the long term

7. Implement the selected alternative

8. Monitor results

Questions:

1. All of the following factors are part of determining effective capacity except:

a. Human

b. External

c. Facility

d. Design

e. all of the above are factors

2. The capacity planning process DOES NOT include which of the following?

a. Estimate future requirements

b. Implement selected alternative

c. Access key quantitative issues

d. Identify alternatives

e. Both a & d

3. All of the following are true of Capacity decisions except:

a. impact the ability of the organization to meet future demands

b. affect operating costs

c. are a major determinant of initial cost

d. are a major determinant of variable cost

e. often involve long term commitment of resources.

4. Which of the following industries measure capacity?

a. Farming

b. Theater

c. Retail Sales

d. Hospital

e. All of the above

5. Which of the following describes the initial cost of an investment?

a. Internal rate of return

b. proceeds

c. Present value

d. cash flow

e. Both a & d

6) Which statement best describes a constraint of capacity planning?

a. Facilitates the performance of a process or system in achieving its goal

b. Limits the performance of a process or system in achieving its goal

c. Enhances the performance of a process or system in achieving its goal

d. Excels the performance of a process or a system in achieving its goal.

e. Maximizes the performance of a process or a system in achieving its goal

7) What are the three primary strategies in capacity planning?

a. growing,leading, tracking

b. leading, moving, tracking

c. leading, following, tracking

d. tracking, analyzing, leading

e. synthesizing, leading, tracking

8) Which of the following is NOT a determinant of effective capacity planning?

a. supply chain

b. external forces

c. human considerations

d. operational factors

e. all the above are determinants of effective capacity planning

9) What are the major difference between design capacity and effective capacity?

a. the size of the facility vs the effectiveness of the facility

b. the design and aesthetics of the facility vs. the size of the facility

c. the design and aesthetics of the facility vs. the effectiveness of the facility

d. the actual amount of output vs. the potential maximum amount of output

e. there is no difference

10) Which answer(s) defines why capacity decisions are important?

a. capacity decisions have a real impact on whether or not a company will meet future demands

b. capacity decisions affect operating costs

c. capacity decisions are generally a major determinant of initial cost

d. capacity decisions affect competitiveness and management

e. all of the above are components of capacity decision importance

11) When would a company incorporate a capacity cushion?

a. when demand is certain

b. when demand is uncertain

c. when the company has very standard products

d. when the company sales are declining

e. when the company sales are increasing

12) Which of the following is a reason a company would want to outsource?

a. The organization does not have the necessary skills

b. The organization has unique quality requirements

c. Demand is high and steady

e. none of the above

13) What is the evidence of an unbalanced system?

a. system is flexible

b. stage of life cycle is taken into account

c. capacity requirements are smoothed out

d. a bottleneck operation exists

e. the company is in the growth phase

14) At the break even point…

a.TC=TR

b. The firm is obtaining a profit

c. TFC=TVC

d. Volume of output is TC > TR

e. none of the above

15) Dis-economies of scale happen when…

a. the output rate is less than the optimal level

b. the firm should increase the output rate in order to decrease average unit costs

c. the output rate is more than the optimal level

d. none of the above

e. both a and b

16) Reasons for strategic capacity planning include all of the following except :

a) Changes in the environment

b) Changes in technology

c) Changes in demand

d) Strengths and weaknesses

e) Opportunities and threats

17) Strategic capacity planning for services differs from that for goods due to:

a) The inability to store services in advance

b) Demand volatility

c) Degree of customization

d) The need for customer convenience

e) All of the above

18) Relevant criteria in determining whether to outsource production include:

a) Location

b) Quality

c) Current in-house capacity

d) Costs

e) All of the above

19) In dis-economies of scale, average unit costs after the optimal level are:

a) Larger

b) Smaller

c) Lowest

d) Constant

e) None of the above

20) Which of the following assumptions must be satisfied in order to use Cost Volume Analysis?

a) Variable cost per unit is greater than revenue per unit

b) Variable cost per unit is constant

c) More than one product in involved

d) Fixed costs change with volume

e) Revenue per unit changes with volume

21) Which of the following is NOT a primary capacity strategy?

a) continuous

b) leading

c) following

d) tracking

e) both b and d

22) Which is an important factor in planning service capacity?

a) availability of capacity

b) the need to be near customers

c) the degree of volatility of demand

d) both b and c

e) none of the above

23)The maximum designed service capacity or output rate is known as?

a) capacity cushion

b) bottleneck operation

c) effective capacity

d) design capacity

e) both c and d

24) Given the following information, compute the efficiency: Effective capacity = 40 trucks per day, Actual output = 36 trucks per day

a) 82%

b) 99%

c) 90%

d) 89.7%

e) 54%

25) Which of the following are steps in the capacity planning process?

a) estimate future capacity requirements

b) conduct financial analysis

c) monitor results

d) implement the selective alternative

e) all of the above

26) Which of these are NOT determinants of effective capacity?

a) Facilities

b) Process Factors

c) Human Factors

d) Policy Factors

e) All of above are determinants of effective capacity

27) What is a constraint?

a) Something that allows a system to perform more effectively and efficiently.

b) Something that hinders performance of a system in achieving its goals.

c) Something that attempts to smooth out capacity requirements.

d) Something that monitors results

e) Something that can never be overcome.

28) Which assumptions must be satisfied in order for cost-volume analysis to be a valuable tool?

a) Variable cost/unit exceeds revenue/unit

b) Everything produced may not be sold

c) Only one product involved

d) Revenue per unit may change depending on volume

e) Variable cost per unit may differ depending on volume

29) What is the correct formula for the break even point in units?

a) FC / (Revenue per unit – VC per unit)

b) VC/(FC-Revenue)

c) Revenue/(VC – FC)

d) FC/(VC-Revenue)

e) None of the above

30) What is the best way to measure capacity for a steel mill?

a) In dollars

b) In number of workers

c) In the size of the mill

d) In tons of steel produced per day

e) In number of resources used

31) What is the first step in the capacity planning process?

A. Evaluate existing capacity

B. Estimate future capacity

C. Determine future capacity price

D. Select alternative capacity

E. Find key quality issues

32) Which of these is a determinant of effective capacity?

A. Facilities

B. Product factors

C. Human factors

D. Operational factors

E. All of these

33) What is the first step in strategy formulation?

A. Determine Product/Service

B. Formulate policy

C. Locate facilities

D. Formulate process

Order operations

34) When is it best to use simulation?

A. For short tem goals

B. For long term goals

C. For current goals

D. For customer wants

E. For “what if” analysis

35) Decision theory is best used in which of the following?

A. Finance

B. Inventory

C. Long term analysis

D. Consumer demand

E. Short term analysis

36) What is capacity?

I. The upper limit or ceiling on the load that an operating unit can handle.

II. The lower limit or bottom on the load that an operating unit can handle.

III. A system’s potential for producing goods or delivering services over a specified time interval.

IV. A ceiling on output and a major determinant of operating costs.

a.) I and II

b.) II and III

c.) I, II, and IV

d.) I, III, and IV

e.) I and IV

37) What is the difference between efficiency and utilization?

a.) Efficiency is the ratio of actual output to effective capacity, while capacity utilization is the ratio of actual output to design capacity.

b.) Efficiency is expressed as a percentage, while capacity utilization is not.

c.) Efficiency is a measure of system effectiveness, while capacity utilization measures capacity tailored to a situation.

d.) Utilization is the ratio of actual output to effective capacity, while efficiency is the ratio of actual output to design capacity.

e.) Utilization is expressed as a percentage, while efficiency is not.

38) Find the design capacity when utilization = 72 and actual output = 36 trucks per day.

a.) 35 trucks per day

b.) 40 trucks per day

c.) 45 trucks per day

d.) 50 trucks per day

e.) 55 trucks per day

39) An operation in a sequence of operations whose capacity is lower than that of the other operations is known as:

a.) Effective Capacity

b.) Design Capacity

c.) Bottleneck Operation

d.) Capacity Cushion

e.) Effective Operation

40) Which of the following is NOT one of the five steps used to resolve constraint issues:

a.) Identify the most pressing constraint.

b.) Change the operation to achieve the maximum benefit, given the constraint.

c.) Make sure other portions of the process are supportive of the constraint.

d.) Explore and evaluate ways to overcome the constraint.

e.) Allow the constraint to limit performance when a strategy is expanding.

| Possible Future Demand | |||

| Alternatives | Low | Moderate | High |

| Small Facility | $10 | $11 | $11 |

| Medium Facility | 7 | 12 | 12 |

| Large Facility | (3) | 2 | 16 |

41. Use the information above to answer this question. If the company uses Maxi-min Criterion to choose the best alternative, what would be the best choice for this company?

a) Small Facility

b) Medium Facility

c) Large Facility

d) Do Nothing

e) They are all incorrect answers.

42. What is Capacity cushion? If utilization is 38%.

a) 72%

b) 74%

c) 12%

d) 22%

e) 62%

| Product | Annual Demand | Standard Processing Time per Unit (Hr) | Processing Time Needed (Hr) |

| 1 | 300 | 5.00 | 1,500 |

| 2 | 400 | 8.00 | 3,200 |

| 3 | 700 | 2.00 | 1,400 |

| Total | 6,100 |

43. Use the information in the table to answer this question. Note: department is working one 8-hour shift 250 days a year. How many machines would be needed to handle the required volume? (Round your answer to the whole number)

a) 3 machines

b) 1 machines

c) 5 machines

d) 2 machines

e) 4 machines

Based on the information below answer the following Questions 44-47.

The owner of Cookies Inc., Zoya, is contemplating adding a new line of cookies, which require leasing for a monthly payment of $4,000. Variable costs would be $2 per cookie, and cookies retail price for $6 each.

44. How many cookies must be sold in order to break-even?

a) 1000 cookies/month

b) 1200 cookies/moth

c) 2100 cookies/moth

d) 1100 cookies/moth

e) None of the above.

45. What would be the profit (loss) if 900 cookies are made and sold in a month?

a) 400 profit

b) 400 loss

c) 4000 profit

d) 4000 loss

e) None of the above.

46. How many cookies must be sold to realize a profit of $10,000?

a) 3500 cookies

b) 5300 cookies

c) 3000 cookies

d) 3200 cookies

e) 2300 cookies

47. If 2,500 cookies can be sold, and a profit is $8,000, what price should be charged per cookie?

a) $7.00

b) $7.50

c) $6.80

d) $6.50

e) $7.80

| Number of Machines | Total Annual Fixed Costs | Corresponding Range of Output |

| 1 | $12,00 | 0 to 300 |

| 2 | 15,000 | 301 to 600 |

| 3 | 24,000 | 601 to 900 |

Variable Cots is $12 per unit, and revenue is $42 per unit.

Use the table above to answer the following Questions 8-10.

48. Determine the break-even point for range (0 to 300).

a) 400 units

b) 320 units

c) 420 units

d) 380 units

e) 520 units

49. Determine the break even point for range (301 to 600).

a) 500 units

b) 400 units

c) 320 units

d) 420 units

e) 520 units

50. If projected annual demand is between 580 and 650 units, how many machines should the manager purchase. If break-even point for

One machine: 400 units Range (0 to 300)

Two machines: 500 units Range (301 to 600)

Three machines: 800 units Range (601 to 900)

a) 2 machines

b) 3 machines

c) 1 machine

d) a&b both are correct

e) None of the above; the manager should do nothing.

51) If the output rate is less than the optimal level, increasing the output rate results in decreasing average unit costs according to:

a) diseconomies of scale

b) economies of scale

c) capacity cushion

d) efficiency

e) utilization

52) If: Design capacity= 60 trucks per day, effective capacity = 40 trucks per day, actual output = 36 trucks per day, compute the efficiency:

a) 20%

b) 30%

c) 40%

d) 50%

e) 90%

54) What is capacity cushion?

a) Extra amount of capacity intended to offset uncertainty in demand

b) Estimate in future capacity requirement

c) Common demand pattern

d) External service or good

e) All of the above

55) What do long term considerations relate to?

a) demand

b) capacity cushion

c) supply

d) overall level of capacity requirements

e) short term events

56) What are the three primary strategies of a strategy formulation?

a. leading, following, and concluding

b. start up, following, and tracking

c. leading, following, and tracking

d. start up, leading, and follow up

e. leading, processing, concluding